KHOPOTSO SLIITER SEKHOLI THIPA

KELELE THIPA

ROTARY THIPA THIPA

THIPA CIGRETTE & PIPE

THIPA E TSOA

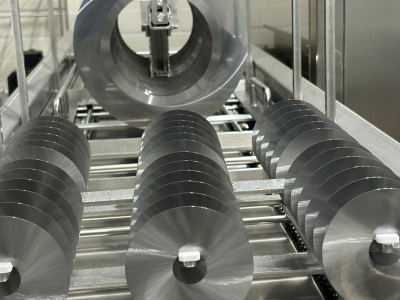

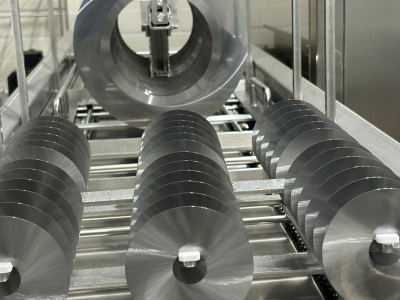

LI-ION BATTERY ELECTRODE THIPA E HLAHANG

LI-ION BATTERY ELECTRODE THIPA E HLAHANG

LI-ION BATTERY ELECTRODE THIPA E HLAHANG

FUMANA MAHALA A BONOLO

HAEBA U KHETHA CARBIDE SLITTING EA RONA

LEHABA, U TLA FUMANA

Ho Slitting ka ho Fetisisa

E entsoe ka premium tungsten carbide, li-blades li fana ka ho nepahala ha sub-micron (± 0.001mm) bakeng sa lisebelisoa tse ntle haholo tsa ho petsoha. Thepa ea ultra-dense, e kopantsoeng le ho belisoa ha seipone (Ra ≤0.02μm), e etsa bonnete ba ho fokotsa li-burr-free (<3μm) ka li-electrode tsa betri tsa lithium.

PHEKO SEBAKA

Ntle le ho bentša, Shen Gong e ka fana ka liphekolo tse ling tse khethehileng tsa holim'a metsi tse fanang ka melemo e kang anti-stick, anti-corrosion, ho hanyetsa oxidation, le ho eketseha ho thata ha holim'a metsi.

Litharollo tsa Tloaelo

Likhetho tsa lintho tse bonahalang: Tungsten carbide & specialty alloys

Customization ea moeli: 27 ° -90 ° angles bakeng sa ts'ebetso e ntlafalitsoeng ea ho itšeha

Sebaka sa bophara: 15mm-400mm ho lumellana le litlhaloso tsa mochine oa hau

Khokahano e se nang moeli: E sebetsa le mefuta eohle e meholo ea lisebelisoa tsa ho seha

Theknoloji ea Tlhahiso ea Lisebelisoa

Ho sebelisa 0.4 ~ 0.8 μm ultra-fine tungsten carbide ho laola ka katleho litšitiso tsa lintlha holim'a mahare a nepahetseng, ho hatella lerōle, 'me ho ntlafatsa haholo ts'ebetso ea ho petsoha ka mokhoa o nepahetseng, ho fella ka boleng bo betere bo sehiloeng.

Boima bo phahameng bo tlisa nako e telele, 'me boima ba HRA bo fihla ho 93.5.

Motsoako o motle oa fracture toughness le matla a flexural o tiisa ts'ebetso e tsitsitseng nakong ea tšebeliso ea lehare.

Lisebelisoa tsa indasteri

E tšeptjoa ke Baetsi ba Battery ba Phahameng ba 3 ba Lefatše

Lithium Battery Electrode (Anode/Cathode) /Separator Battery (PP/PE/Ceramic Coated) / Copper/Aluminium Slitting

Ho Seha ha Burr-Free

Theknoloji ea ho sila ka mokhoa o nepahetseng haholo e fokotsa li-burrs (<5μm), e netefatsa hore li-electrode tse boreleli.

Khatello ea Lerōle & Karolo

Ho roala ha anti-static ho fokotsa ho khomarela lerōle, ho ntlafatsa chai ea kopano ea lisele.

Ha ho na Wavy Edges

Geometry ea blade e ntlafalitsoeng e thibela deformation ea thepa, e tlosa methapo ea wavy.

Ho feta lilemo tse 20 Setsebi sa Carbide

Lithipa le Li-Blades tsa indasteri

Lihlahisoa tse ka sehloohong tsa k'hamphani li kenyelletsa lithipa tsa carbide le cermet, li-blades tse sehang, li-blades tse petsolang, lisebelisoa tsa ho seha, likarolo tse sa senyeheng le lisebelisoa tse amanang le tsona.

SG ka

machaba

pontsho

PAKA

&

KEKEPE

TS'ELISO TS'ELISO

HLAHISO KAKARETSO

TLHOKOMELISO E HLAHISITSENG LE E EKETSENG

Shen Gong e sebelisa haholo CNC le lisebelisoa tsa ts'ebetso tse ikemetseng litsing tsa eona tsa tlhahiso, ka lits'ebetso tse ling tsa bohlokoa tse sebelisang lisebelisoa tse tsoang kantle ho naha ho netefatsa botsitso ba boleng ba batch.

Precision Machining

Theknoloji ea machining e nepahetseng ea Shen Gong e netefatsa hore botenya, ho bata, ho bapisa, le ho otloloha ha lithipa li laoloa ho ea boemong ba micron (μm). Bokhopo ba sefahleho bo ka fihla ka tlase ho Ra0.02, ho fihlela seipone se felletseng.

Lilemo tsa boiphihlelo ba Shen Gong ho mahlale a ho sila a thipa a liindasteri a ka laola bofokoli ba ntlha ho isa boemong ba micron (μm).

Theknoloji e phahameng e nepahetseng ea ho sebetsa ka bohale e tiisa hore thipa e bohale ha e ntse e phahamisa 300x kapa tlhahlobo e phahameng bakeng sa "mefokolo ea zero."

MOLAOLI KHABANE

Li-blades Bakeng sa Likopo tsa ho Seha Liindasteri

HAEBA U KHETHA CARBIDE SLITTING EA RONA

LEHABA, U TLA FUMANA

Ho Slitting ka ho Fetisisa

E entsoe ka premium tungsten carbide, li-blades li fana ka ho nepahala ha sub-micron (± 0.001mm) bakeng sa lisebelisoa tse ntle haholo tsa ho petsoha. Thepa ea ultra-dense, e kopantsoeng le ho belisoa ha seipone (Ra ≤0.02μm), e etsa bonnete ba ho fokotsa li-burr-free (<3μm) ka li-electrode tsa betri tsa lithium.

PHEKO SEBAKA

Ntle le ho bentša, Shen Gong e ka fana ka liphekolo tse ling tse khethehileng tsa holim'a metsi tse fanang ka melemo e kang anti-stick, anti-corrosion, ho hanyetsa oxidation, le ho eketseha ho thata ha holim'a metsi.

Litharollo tsa Tloaelo

Likhetho tsa lintho tse bonahalang: Tungsten carbide & specialty alloys

Customization ea moeli: 27 ° -90 ° angles bakeng sa ts'ebetso e ntlafalitsoeng ea ho itšeha

Sebaka sa bophara: 15mm-400mm ho lumellana le litlhaloso tsa mochine oa hau

Khokahano e se nang moeli: E sebetsa le mefuta eohle e meholo ea lisebelisoa tsa ho seha

Theknoloji ea Tlhahiso ea Lisebelisoa

Ho sebelisa 0.4 ~ 0.8 μm ultra-fine tungsten carbide ho laola ka katleho litšitiso tsa lintlha holim'a mahare a nepahetseng, ho hatella lerōle, 'me ho ntlafatsa haholo ts'ebetso ea ho petsoha ka mokhoa o nepahetseng, ho fella ka boleng bo betere bo sehiloeng.

Boima bo phahameng bo tlisa nako e telele, 'me boima ba HRA bo fihla ho 93.5.

Motsoako o motle oa fracture toughness le matla a flexural o tiisa ts'ebetso e tsitsitseng nakong ea tšebeliso ea lehare.

Lisebelisoa tsa indasteri

E tšeptjoa ke Baetsi ba Battery ba Phahameng ba 3 ba Lefatše

Lithium Battery Electrode (Anode/Cathode) /Separator Battery (PP/PE/Ceramic Coated) / Copper/Aluminium Slitting

Ho Seha ha Burr-Free

Theknoloji ea ho sila ka mokhoa o nepahetseng haholo e fokotsa li-burrs (<5μm), e netefatsa hore li-electrode tse boreleli.

Khatello ea Lerōle & Karolo

Ho roala ha anti-static ho fokotsa ho khomarela lerōle, ho ntlafatsa chai ea kopano ea lisele.

Ha ho na Wavy Edges

Geometry ea blade e ntlafalitsoeng e thibela deformation ea thepa, e tlosa methapo ea wavy.

Ho feta lilemo tse 20 Setsebi sa Carbide

Lithipa le Li-Blades tsa indasteri

Lihlahisoa tse ka sehloohong tsa k'hamphani li kenyelletsa lithipa tsa carbide le cermet, li-blades tse sehang, li-blades tse petsolang, lisebelisoa tsa ho seha, likarolo tse sa senyeheng le lisebelisoa tse amanang le tsona.

SG ka

machaba

pontsho

PAKA

&

KEKEPE

TS'ELISO TS'ELISO

HLAHISO KAKARETSO

TLHOKOMELISO E HLAHISITSENG LE E EKETSENG

Shen Gong e sebelisa haholo CNC le lisebelisoa tsa ts'ebetso tse ikemetseng litsing tsa eona tsa tlhahiso, ka lits'ebetso tse ling tsa bohlokoa tse sebelisang lisebelisoa tse tsoang kantle ho naha ho netefatsa botsitso ba boleng ba batch.

Precision Machining

Theknoloji ea machining e nepahetseng ea Shen Gong e netefatsa hore botenya, ho bata, ho bapisa, le ho otloloha ha lithipa li laoloa ho ea boemong ba micron (μm). Bokhopo ba sefahleho bo ka fihla ka tlase ho Ra0.02, ho fihlela seipone se felletseng.

Lilemo tsa boiphihlelo ba Shen Gong ho mahlale a ho sila a thipa a liindasteri a ka laola bofokoli ba ntlha ho isa boemong ba micron (μm).

Theknoloji e phahameng e nepahetseng ea ho sebetsa ka bohale e tiisa hore thipa e bohale ha e ntse e phahamisa 300x kapa tlhahlobo e phahameng bakeng sa "mefokolo ea zero."

MOLAOLI KHABANE

Li-blades Bakeng sa Likopo tsa ho Seha Liindasteri