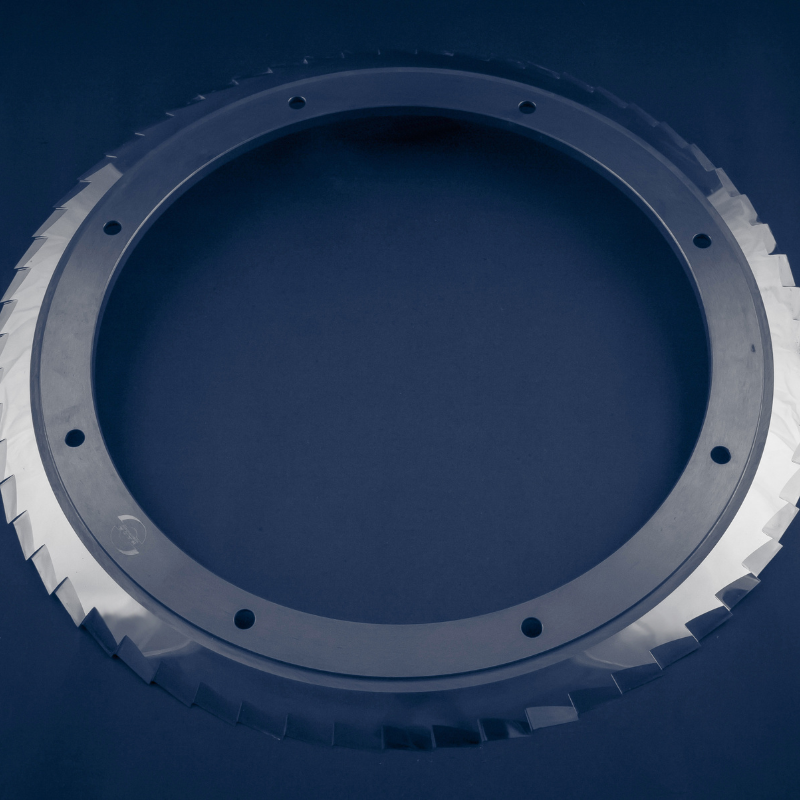

CORRUGATEDE SLIITER SCORER KNIFE

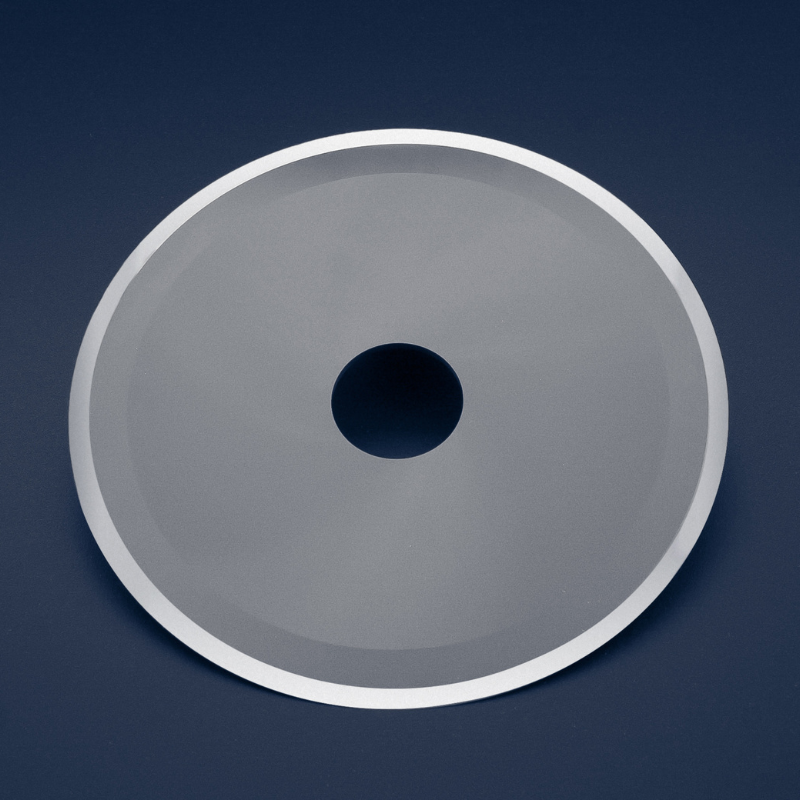

COIL SLITTING KNIFE

ROTARY TRIMMER KNIFE

CIGRETTE &PIPE KNIFE

WINDING KNIFE

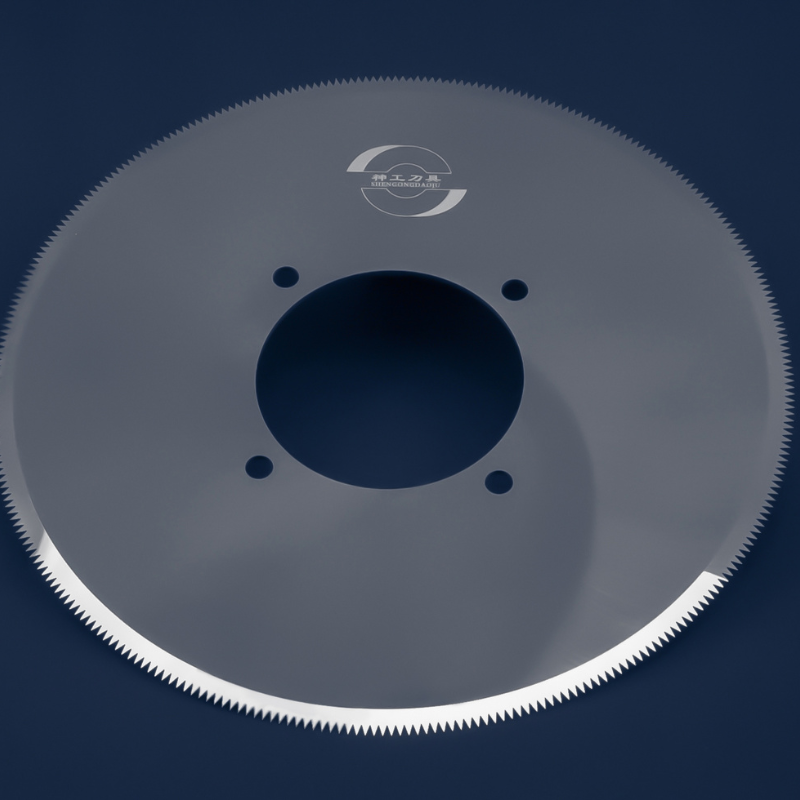

LI-ION BATTERY ELECTRODE SLITTING KNIFE

LI-ION BATTERY ELECTRODE SLITTING KNIFE

LI-ION BATTERY ELECTRODE SLITTING KNIFE

GET YOUR FREE SIMPLE

IF YOU CHOOSE OUR CARBIDE SLITTING

BLADE,YOU WILL GET

Ultra-Precision Slitting

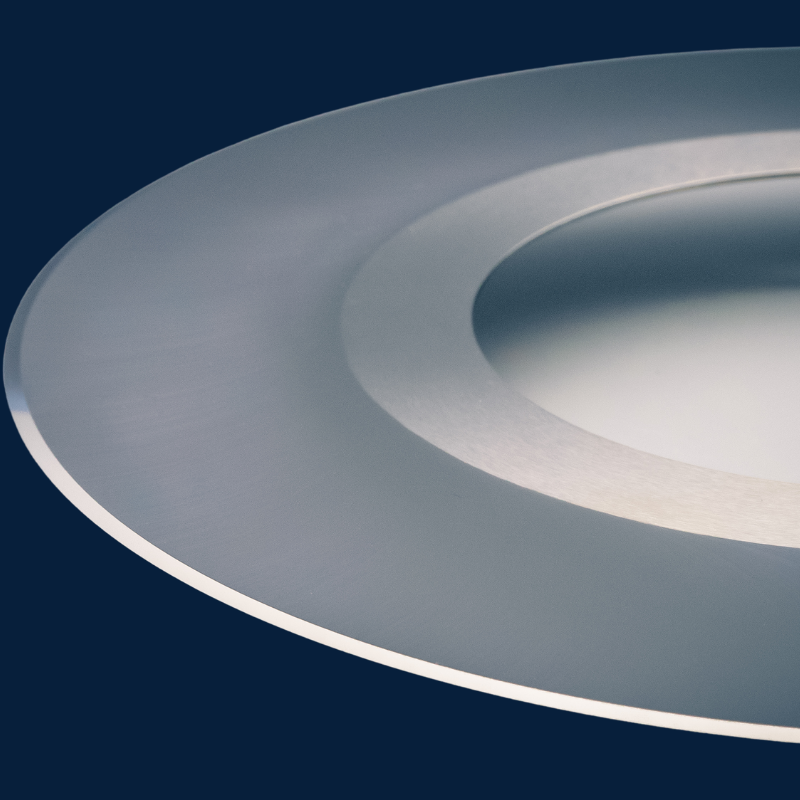

Engineered with premium tungsten carbide, blades deliver sub-micron precision (±0.001mm) for ultra-fine slitting applications. The ultra-dense material, combined with mirror-edge polishing (Ra ≤0.02μm), ensures burr-free cuts (<3μm) in lithium battery electrodes.

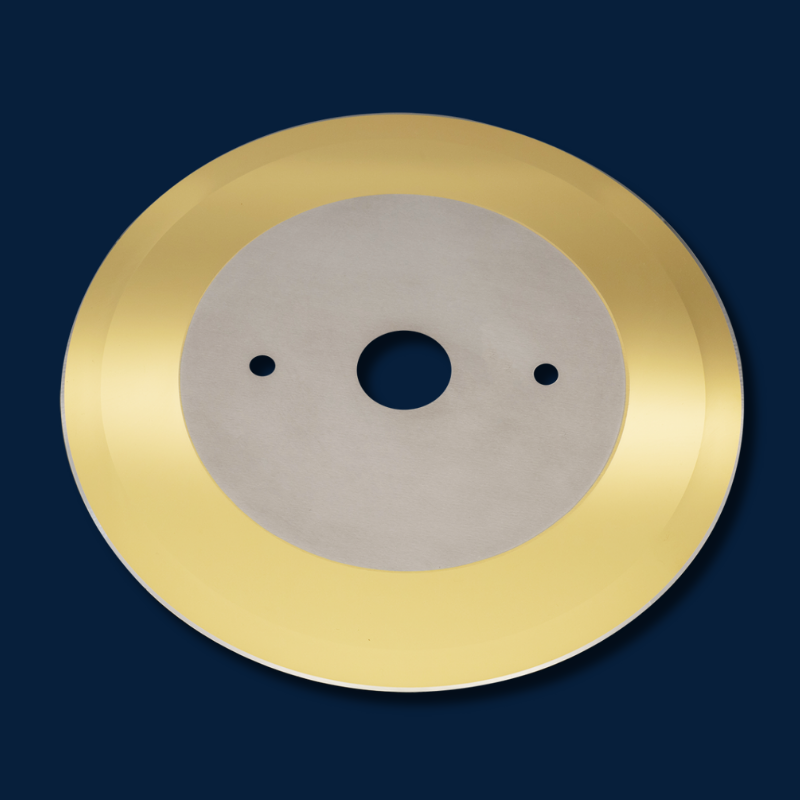

SURFACE TREATMENT

In addition to polishing, Shen Gong can provide other special surface treatments that offer benefits such as anti-stick, anti-corrosion, oxidation resistance, and increased surface hardness.

Custom Solutions

Material options: Tungsten carbide & specialty alloys

Edge customization: 27°-90° angles for optimized cutting performance

Diameter range: 15mm-400mm to fit your machine specifications

Seamless compatibility: Works with all major slitting equipment brands

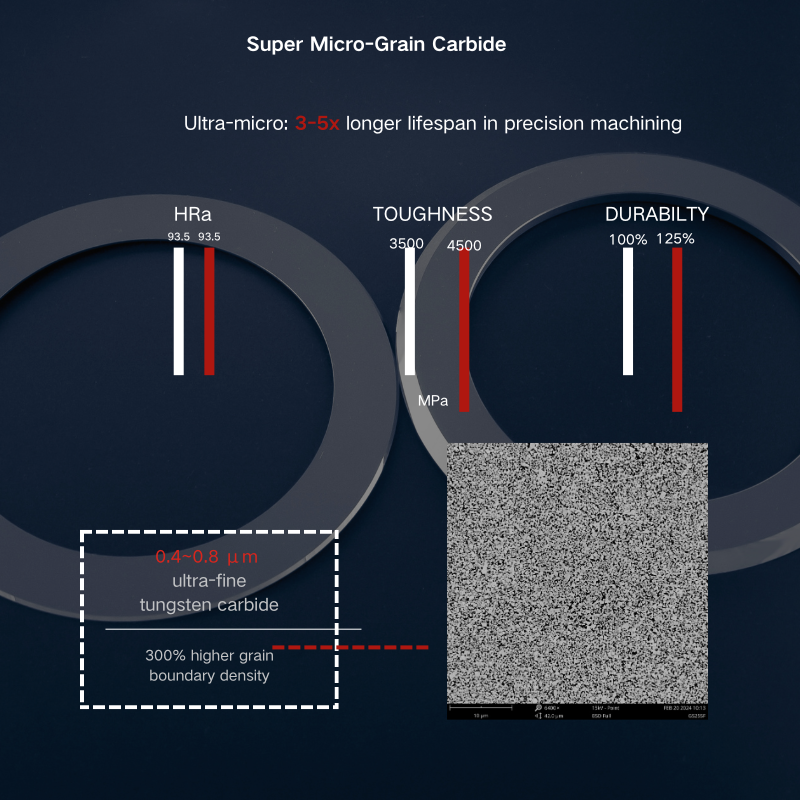

Materials Manufacturing Technology

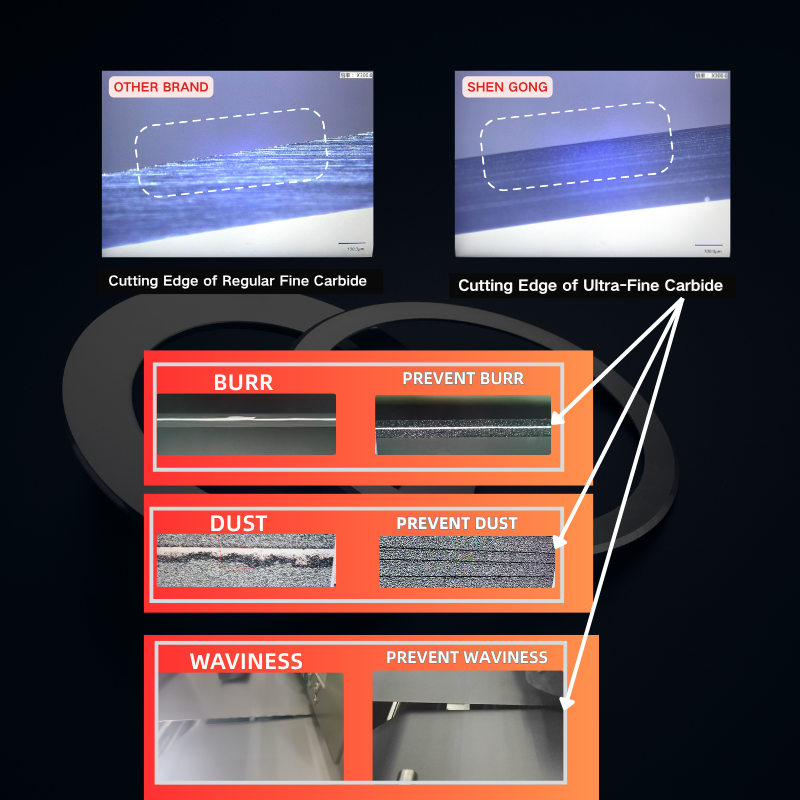

Utilizing 0.4~0.8 μm ultra-fine tungsten carbide effectively controls tip defects on precision blades, suppresses dust, and significantly enhances precision slitting performance, resulting in better cut quality.

High hardness brings excellent durability, with HRA hardness reaching up to 93.5.

The combination of good fracture toughness and flexural strength ensures more stable performance during blade use.

Industry Applications

Trusted by Top 3 Global Battery Manufacturers

Lithium Battery Electrode (Anode/Cathode) /Battery Separator (PP/PE/Ceramic Coated) / Copper/Aluminum Slitting

Burr-Free Cutting

Ultra-precision grinding technology minimizes edge burrs (<5μm), ensuring smooth electrode edges.

Dust & Particle Suppression

Anti-static coating reduces dust adhesion, improving cell assembly yield.

No Wavy Edges

Optimized blade geometry prevents material deformation, eliminating wavy edges.

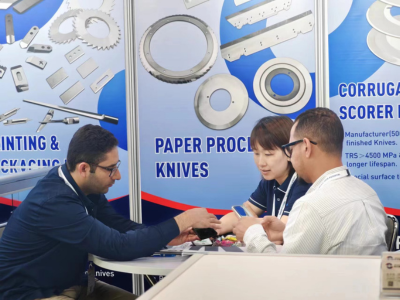

Over 20 Years Expert In Carbide

Industrial Knives and Blades

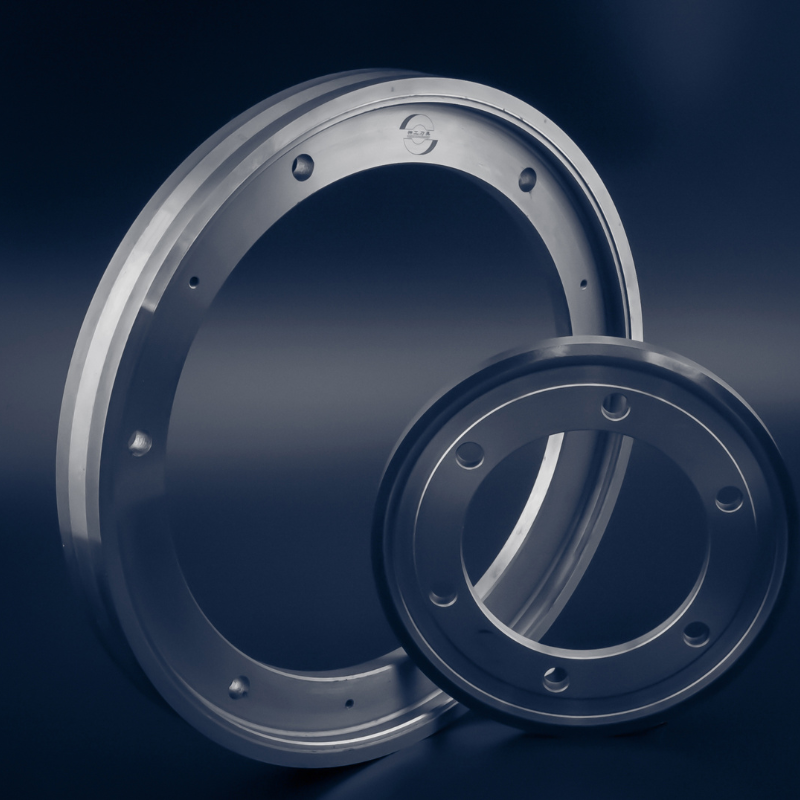

The company's main products include carbide and cermet slitting knives, cutting blades, shredding blades, cutting tools, wear-resistant parts, and related accessories.

SG in

international

exhibition

PACKING

&

SHIPPIING

ISO CERTIFIED

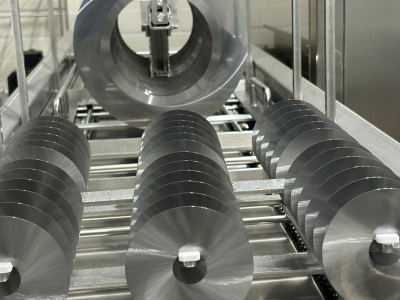

PRODUCTION OVERVIEW

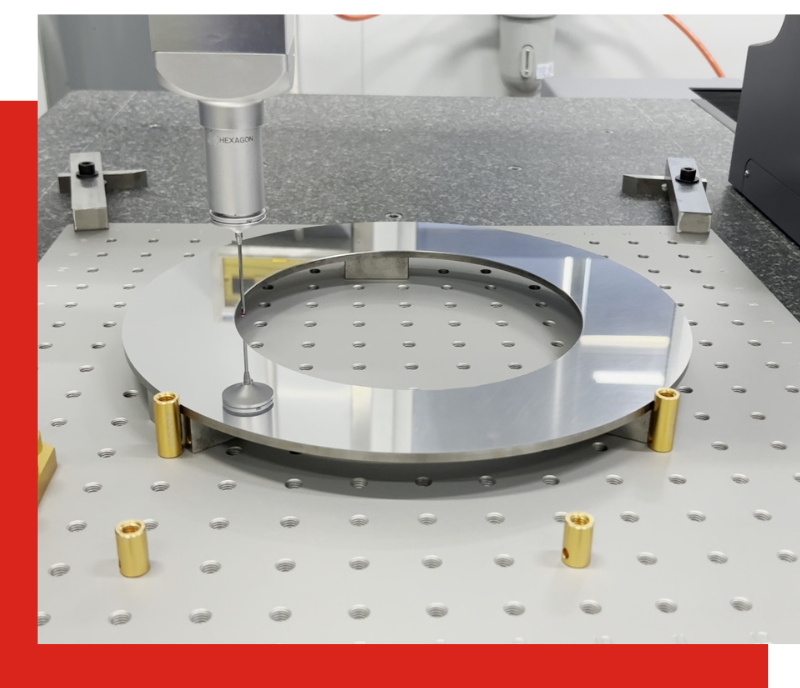

DIGITALIZED & STANDARDIZED PRODUCTION

Shen Gong extensively utilizes CNC and automated processing equipment in its production facilities, with some key processes employing world-leading imported equipment to effectively ensure batch quality stability

Precision Machining

Shen Gong's precision machining technology ensures that the thickness, flatness, parallelism, and straightness of knives are controlled to the micron (μm) level. Surface roughness can reach below Ra0.02, achieving a full mirror finish.

Shen Gong’s years of expertise in industrial knife edge grinding technology can control edge tip defects to the micron (μm) level.

High-precision special edge processing technology ensures knife sharpness while upporting 300x magnification or higher inspection for "zero defects."

QUALITY CONTROL

Blades For Industrial Cutting Applications