Products

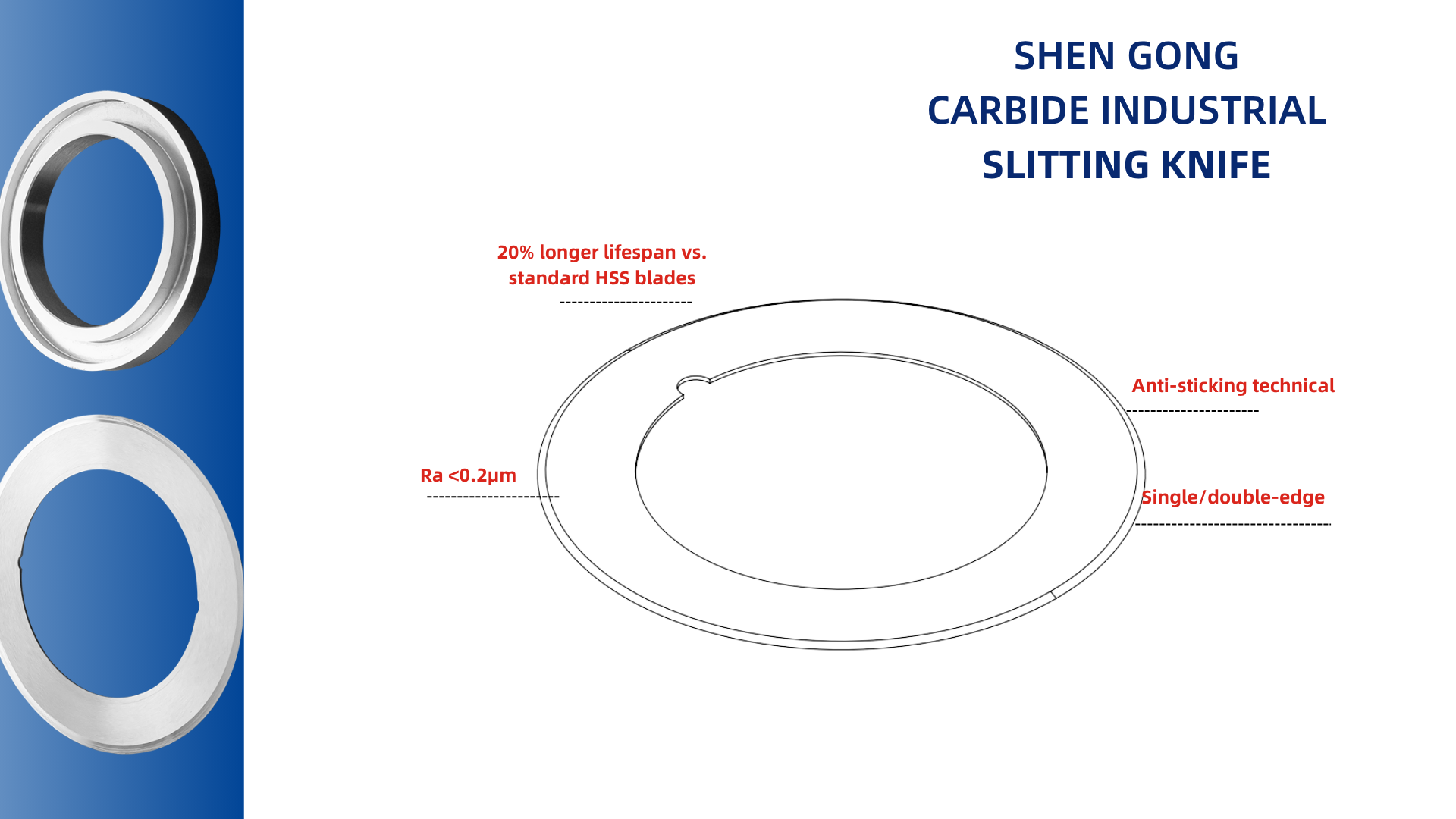

Tungsten Carbide Circular Slitting Knives for Lithium Battery Separator Films

Detailed Description

SG Carbide Knives makes tough circular blades for cutting lithium battery films. Our blades are different because we use solid tungsten carbide that lasts much longer than ordinary blades. Top battery companies like CATL and ATL use our blades every day in their production because they deliver clean cuts without burrs or dust. The secret is in our special manufacturing process that makes the blades denser and sharper. When you need blades that won't wear out quickly and can handle thin battery films perfectly, try ours. We can send samples in just 3 days so you can see the difference yourself. Good blades mean fewer production problems and better quality battery separators - that's what we deliver. Designed for 5μm+ precision slitting, our blades minimize edge defects and eliminate sticking/peeling—perfect for wet/dry process separators in EV, ESS, and 3C batteries.

Already adopted by Top 3 Chinese battery giants (CATL, ATL, Lead Intelligent), SG’s tungsten carbide slitting blades ensure:

✔ 20% longer lifespan vs. standard HSS blades

✔ Ra <0.2μm cut surface with anti-sticking coating

✔ Single/double-edge designs for adjustable slit widths

Features

Ultra-Dense Carbide Material – 92.5% tungsten content for wear resistance in high-speed slitting (200+ m/min).

Submicron Edge Control – Laser-polished prevents filamentation & dusting.

Flatness ≤0.003mm – Ensures stable tension for ceramic-coated/PVDF separators.

OEM Flexibility – Custom diameters, bore sizes, and HRC 90+ hardness.

ISO 9001 Certified – Batch-tested for consistent quality.

Specifications

| Items | (øD*ød*T)mm | |

| 1 | φ68φ46*0.5 | Top Blade |

| 2 | φ69*φ46*0.5 | Lower Blade |

| 3 | φ72*φ46*0.5 | Top Blade |

| 4 | φ98*φ66*0.7 | Lower Blade |

| 5 | φ60φ40*5 | Top Blade |

| 6 | φ80*φ55*10 | Lower Blade |

Applications

▸ Power Batteries – NCM/NCA anode/cathode separators

▸ Energy Storage – Thick-film PP/PE slitting

▸ 3C Batteries – Ultra-thin PVDF/PVA films

Q&A

Q: MOQ & lead time?

A: 10 pcs, delivered in 30-35 days with expedited options.

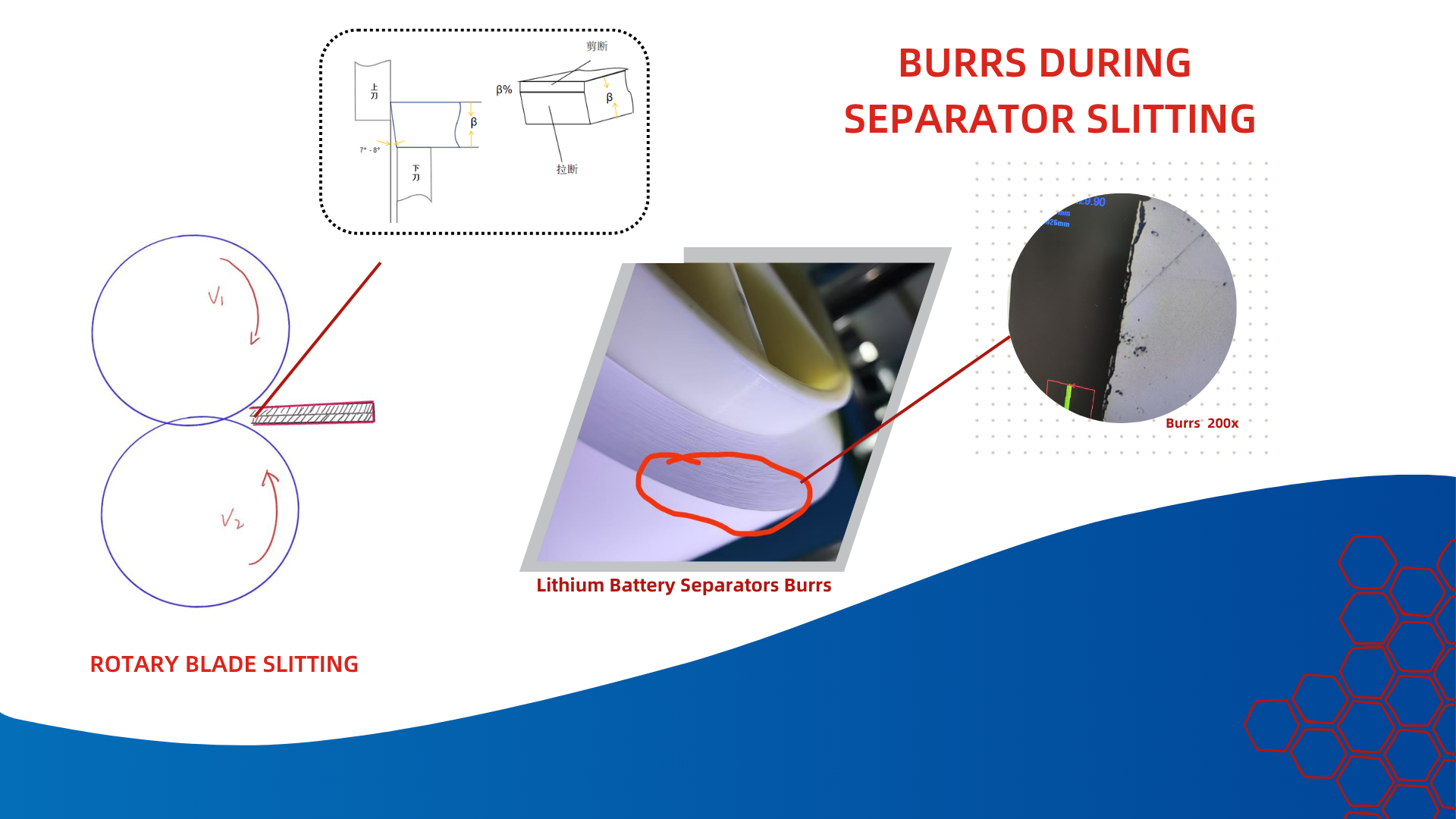

Q: How to reduce burrs in 7μm PET separators?

A: Use our dual-edge round knife with single edge angle—ATL-approved for <0.1μm burr tolerance.

Q: Compatible with Nakamoto/Fujipla slitters?

A: Yes! Provide machine specs for plug-and-play fit.