Knives Applications in the Corrugated Industry

With the rapid expansion of the express packaging market, the use of corrugated paper is becoming increasingly widespread. Traditional corrugated paper knives suffer from poor cutting accuracy, which can easily lead to burrs and glue, impacting product quality. With 22 years of experience in the industry, Shengong provides customers with high-performance knives with anti-stick coatings, solving a range of industry challenges, including multi-layer corrugated paper slitting.

Since our establishment, we have provided customized knive solutions to over 100 corrugated paper manufacturers worldwide.

Industry Challenges

Common knives can encounter the following problems when used in complex corrugated paper processing:

√Low cutting accuracy and uneven cuts

√Short knive life, requiring frequent replacement

√Paper debris adheres to the knive during cutting, impacting production efficiency

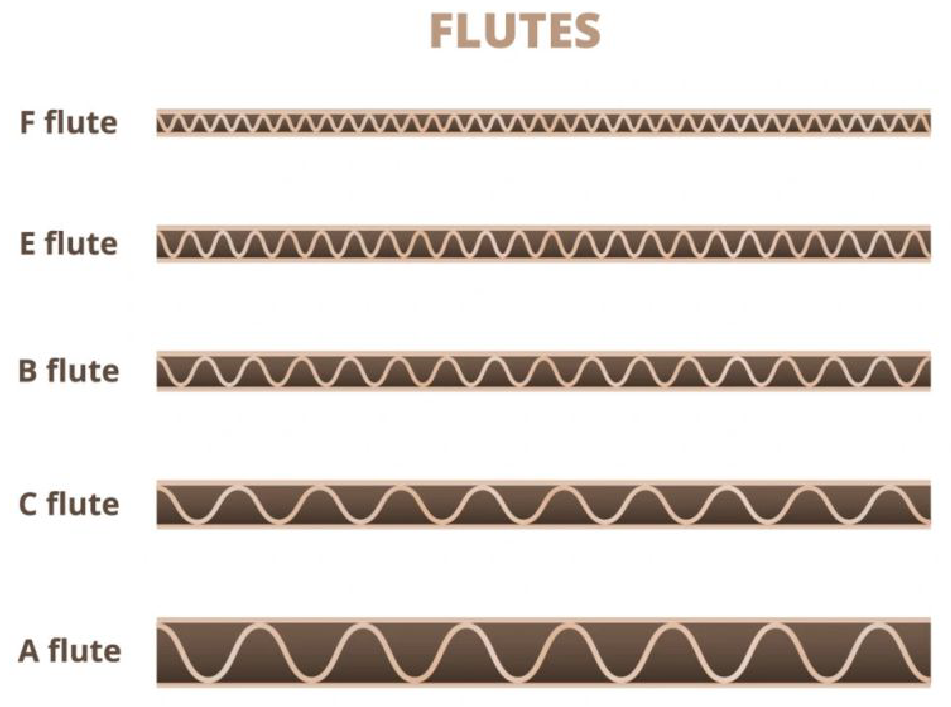

√Difficulty handling corrugated paper of varying thicknesses and hardnesses

√Excessive knive wear during cutting, leading to production interruptions

√Customers need to improve cutting efficiency and reduce production downtime

Corrugated manufacturers, how do you choose the right knive for your needs?

Material: When cutting thick or rigid corrugated paper, which has high hardness and density, you need to select a knive with high hardness and wear resistance, and the blade angle should generally be above 20°. A blade angle that is too small is not conducive to chipping resistance. Tungsten steel knives are currently the best knives on the market. When cutting thinner and softer corrugated paper, you need to select a blade angle below 20° for high cutting accuracy.

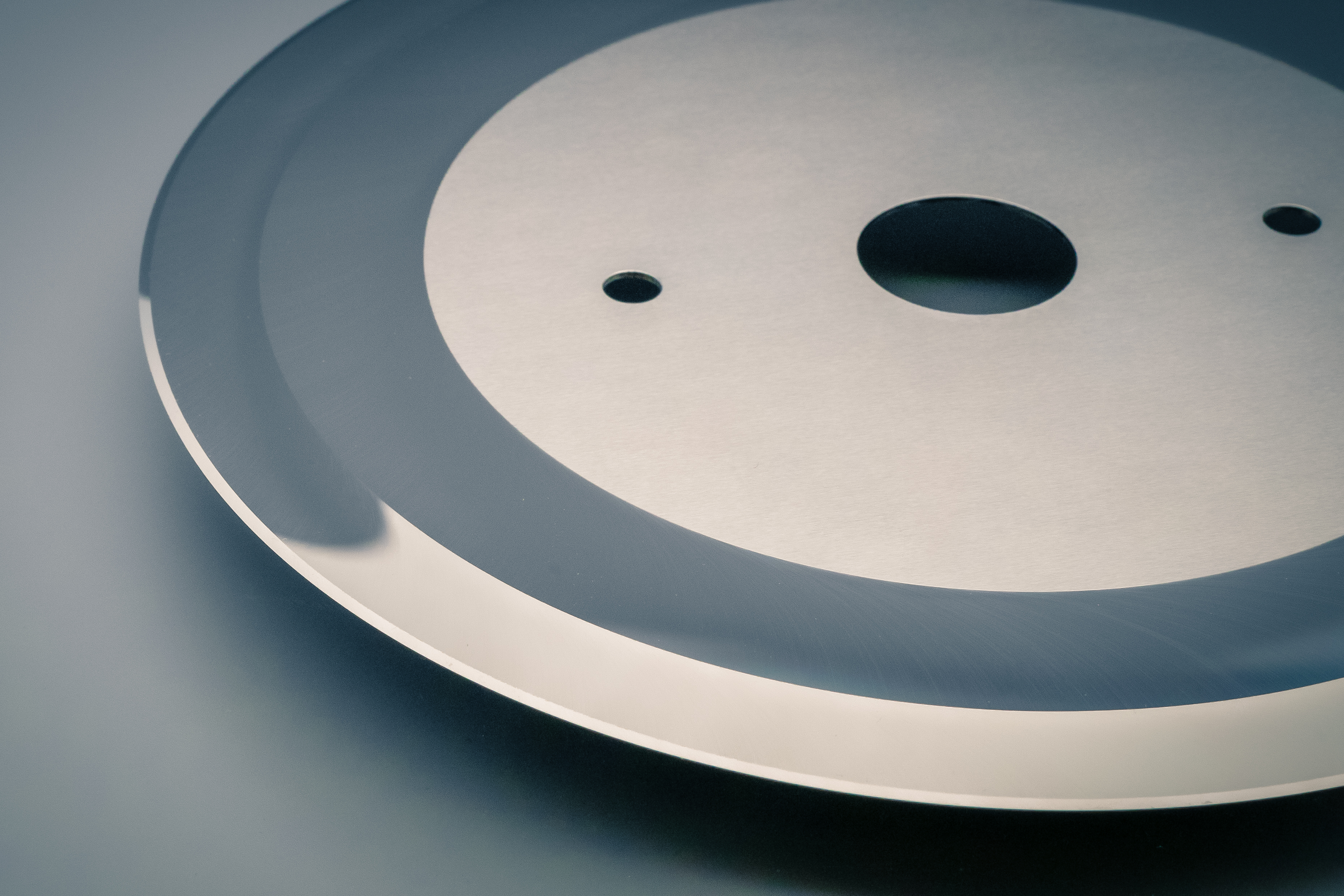

Cutting Conditions: When cutting continuously for extended periods of time or for large-scale production, multi-purpose slitting knives, such as high-efficiency carbide circular cutters, can be selected. These knives can adapt to different types of corrugated paper, reducing knive changes and improving production line efficiency.

knive Coating: If the corrugated has special coatings (such as waterproof or antistatic coatings), choose carbide knives with an anti-stick coating (such as PTFE or titanium) to prevent the coating from sticking to the knive and maintain a smooth cutting process.

knive Shape and Size: Choose the knive shape (straight, circular) and size based on the cutting process. For complex cutting processes (such as circular cutting or cutting multiple layers of corrugated paper), specially designed carbide knives can be selected.

Features of Shengong knives

Our current kniveing options include:

① Corrugated slitter scorer knife

② Premium corrugated slitter scorer knife

③ Anti-sticking (ATS) corrugated slitter scorer knife

④ PVD coated corrugated slitter scorer knife

⑤ Sharpening wheel

⑥ Cross cutting knife

For other customized kniveing needs, please contact the Shengong team at howard@scshengong.com.

PVD Coated corrugated slitter scorer knife

Premium Tungsten Carbide Corrugated Slitter Scorer Knife